Anjing Road, Xiaolan, Zhongshan, Guangdong, China

info@mes-drive.com

08.00 AM-09.00 PM

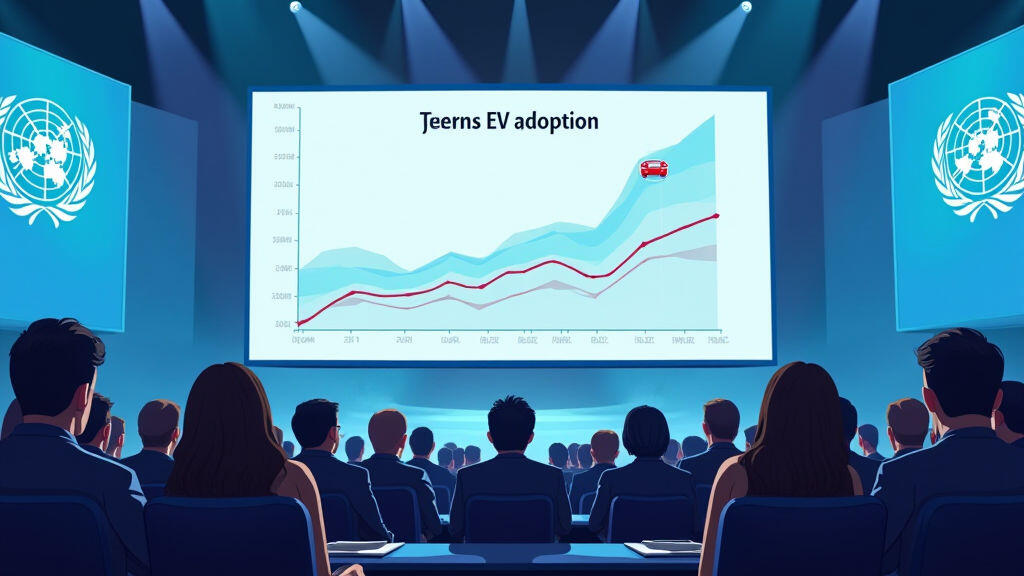

In late September, the United Nations Climate Action Summit in Kigali announced an ambitious target: by 2030, the global automotive sector should have shifted 75 % of new vehicle sales to zero‑emission models. This headline‑making pledge came after years of soaring CO₂ emissions and spurred governments across continents to accelerate their entry‑into-the-second‑generation electric‑vehicle (EV) market. For manufacturers, the challenge is no longer just about batteries or software—it’s also about the heart of the drivetrain: the gear motor, also known as the reducer motor.

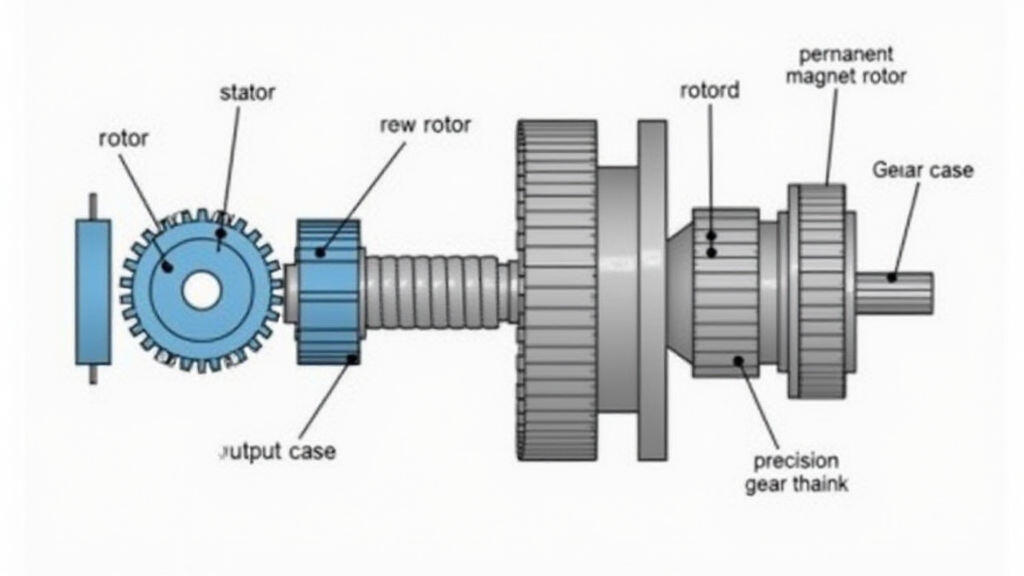

A gear motor is a compact unit that combines an electric motor with a gear train, reducing the high-speed output of the motor to a lower speed with high torque. In EVs, this reduction is essential: the electric motor’s shaft typically spins at 10,000 + rev/min, while the wheels require slow, torque‑rich motion. By integrating the reduction mechanism into a single module, gear motors cut mechanical complexity, save space, and reduce weight—critical factors for battery‑powered vehicles.

Unlike traditional motor‑gearbox pairs, which suffer from additional shafts, bearings, and housing, a gear motor presents a sealed, single‑piece solution. This reliability is vital for meeting the stricter durability and safety standards now being imposed on EVs by European and Asian regulatory bodies.

The UN announcement triggered a domino effect of policy changes. Within a month, the EU finalized a mandate that all new cars sold in its 27‑nation market must have a minimum 75 % battery-electric (BEV) or plug‑in hybrid (PHEV) option by 2035. China’s “New Energy Vehicle” quotas saw a boost from 70 % to 80 % in 2024, while India announced a “Zero‑Emission Vehicle” incentive program that would provide tax exemptions for EVs produced by 2028.

These policy pushes dramatically raise the volume of EVs that must be produced annually. Manufacturers respond by designing lighter and more efficient drivetrains, and the gear motor sits at the core of that redesign. A superior reducer motor can provide higher efficiency, shorter motor size, and lower peak torque, enabling tighter packaging of the battery pack and simplifying the overall architecture.

In addition, the new regulations demand stricter emissions standards for EV charging infrastructure, leading to the adoption of higher power inverters and motors. Gear motors that operate efficiently at higher currents and voltages provide a sure route to meet these evolving specifications.

Recent breakthroughs in magnetic material science and additive manufacturing have made it possible to produce gear motors with unprecedented performance. Researchers at the University of Tokyo have recently published a paper on 3D‑printed permanent‑magnet materials with improved heat dissipation. Combined with precision gear tooth profiles printed in high‑grade steel, these motors can exceed 89 % efficiency—a 4 % improvement over typical commercial units.

Moreover, the integration of “smart” sensors directly into the gear motor housing has opened new avenues for predictive maintenance. Embedded Hall effect sensors can monitor slip, temperature, and torque, allowing vehicle software to detect early signs of wear. This feature aligns perfectly with the trend toward “connected” and autonomous vehicles, where real‑time diagnostics are critical for safety.

Consumers now expect EVs to be as fast, as reliable, and as convenient as gasoline cars. Automotive makers like Tesla, Volkswagen, and Hyundai are racing to reduce battery weight by incorporating lighter, high‑power motors. A reduction in motor size translates directly to space saved for batteries,’ pushing the range envelope further.

Furthermore, the rise of shared‑mobility platforms—Uber, Lyft, city‑wide EV bus fleets—has increased the importance of rapid charging and robust performance. Shared fleets require motors that can handle frequent, high‑profile acceleration cycles while maintaining longevity. Rigorous gear motor designs that feature hardened gear teeth and low–slip bearings meet this dual requirement.

The automotive industry’s shift toward modular, plug‑and‑play components is making the gear motor a natural fit. By offering a fully integrated motor–gear solution, manufacturers can swap motor modules across multiple vehicle platforms with minimal redesign effort. This modularity simplifies supply chains, reduces inventory costs, and speeds time‑to‑market for new EV models.

In Asia, part‑buyers such as Moog and Bosch have announced partnership programs to supply standardized “dog‑bone” gear motors to OEMs. The result? A standardized approach to drivetrain design that encourages mass production and quality control at a global scale, supporting the push toward mass‑market EV penetration.

The Kigali UN Climate Summit has set a clear urgency: reduce transportation’s carbon footprint by 2030. Against this backdrop, the gear motor emerges as a pivotal technology that transforms electric inches into practical miles. Whether through breakthroughs in material science, smart sensor integration, or modular design, reducer motors are poised to meet the soaring demands of tomorrow’s EVs—providing power, efficiency, and durability at a scale never before seen.

As governments tighten emissions targets, consumers shift expectations, and manufacturers adapt their platforms, the gear motor will be the silent—and essential—force that carries our global transition to cleaner transportation.

Leave A Reply

Your email address will not be published. Required fiels are marked